Dr. Beatriz Molero Sanchez is transforming CO2 into profits

By Mitchell Brown

This year’s Mitacs Environmental Entrepreneur Award winner, Beatriz Molero Sanchez didn’t start out looking to save the planet – we can thank her music teacher for setting her on that path.

“I started learning music when I was little,” she says. “Music theory is really complicated, and it’s all math – and because of that love of math, I later realized I loved science. I took chemistry because I was fascinated by it. It connects everything – it touches absolutely everything.”

After completing her master’s degree in chemistry at the Universidad Complutense de Madrid, Sanchez moved from her native Spain to Calgary in 2011 where, as part of the Trans-Atlantic Science Student Exchange Program, she continued her research and completed a PhD while studying under Dr. Viola Birss, a world-renowned expert in electrochemistry (see sidebar). In partnership with another PhD student, Paul Addo, Sanchez recently turned her passion into launching SeeO2 Energy Inc., a clean-tech company focused on converting waste carbon dioxide into marketable and clean, high-value fuels and chemicals by using reversible fuel-cell technology.

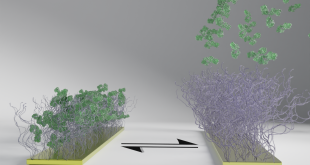

The process, which is focused on high-temperature electrolyzers and relies on a proprietary high-performance electrocatalyst material, can co-electrolyze water and captured CO2 to produce syngas (a mixture of carbon monoxide and hydrogen) – a substance that can be converted into methanol, ammonia, substitute natural gas or synthetic liquid fuels. Or, the molecule can be broken down into carbon monoxide and pure oxygen, with the former used in such industries as electronics, fertilizer and polymer production and the latter used in medicine, among other fields.

At the heart of SeeO2’s technology are circular building blocks, or cells, that come together to form stacks that capture carbon emissions. The cells that Sanchez worked on during her PhD were about one cm2 in area; their benchtop prototype consists of 15 larger cells (10×10 cm) grouped together in a “tall stack” to convert about 10 kg of CO2 per day.

The idea is to place a monetary value on a company’s CO2 emissions, giving that company an incentive to capture and commodify those emissions instead of letting them fly off into the atmosphere and push record atmospheric CO2 levels even higher. “We’re trying to stop the increase of greenhouse gas emissions, and eventually reduce them,” Sanchez explains. “At the same time, we’re monetizing the process by giving businesses a valuable asset at the end. We need to have economically viable technologies so that industry will be willing to adopt them.”

It’s such a brilliantly simple idea – turning waste products into usable goods – that it’s tempting to ask why anyone hasn’t thought about doing this before. They have, Sanchez admits, but it’s not as easy as you might think.

“CO2 is a really stubborn molecule,” she says, explaining how the chemical properties of carbon dioxide – the same properties that lead to it being a long-lasting gas in the atmosphere – make it difficult to break apart and turn into other useful chemicals. But she and her team are proving that it can be done. “Like everything, it’s cheaper as you scale up – look at how far we’ve come with solar panels. But it takes a long time.”

In just over a year, the company has grown to three full-time employees, 10 industry advisors and five board members. They have completed a successful benchtop prototype, and the company is now securing $1.5 million in seed funding to develop a larger-scale field test unit, with testing scheduled to start in the spring of 2020.

The first companies to test the technology include a U.S.-based green plastic producer and ATCO Energy, a natural gas and electricity retailer. Commercial shipments are expected to start in 2021.

“If our commercial-scale units were to be used by our end users, such as green plastics or petrochemicals producers, we would significantly decrease CO2 emissions equivalent to removing 100 million cars off the roads or 700,000 jet planes out of the skies. This technology has the potential to be used worldwide,” Sanchez explains, adding that companies in Europe and Asia are already expressing interest. “Taking research out of the lab and into the real world – it’s super important. We should be aware of what universities are doing, and how industry can help.”

BioLab Business Magazine Together, we reach farther into the Canadian Science community

BioLab Business Magazine Together, we reach farther into the Canadian Science community