A diverse and multitalented lab in PEI, Bio|Food|Tech has its fingers in several pies

By Hermione Wilson

Bio|Food|Tech is a bustling lab on Prince Edward Island with a staff of 23 people, five of whom are PhDs. The company provides microbial analysis, food safety workshops, on-site nutrition label services, product development services and a host of other functions.

The company is owned by the government of PEI which covers 40 per cent of the lab’s total budget. The remainder comes from work done on a fee-for-service basis. The lab’s main role is to support the local food and beverage industry.

“About half of the work we do in total would be lab work, traditional lab work if you like, and the rest would be broader than that,” says Executive Director Jim Smith. Much of the lab work involves food safety, he says, though it also does work for the biotechnology sector. The other half of the organization is involved in “project activity,” that is, working with industry clients on innovation projects and new product development in any of its four pilot plants (two dedicated to food and two to biotech).

“What we do is, and it’s in our titling, is ‘Concept to pilot to market.’ So we help companies to come up with ideas for new products and take them through the development process,” Smith says. “The lab is involved in all of that, right from the development of the products through to the scale-up in the lab, development of processes, as well as the analysis of products to make sure that they’re safe for the marketplace.”

Bio|Food|Tech’s lab is accredited for a range of different tests by Standards Council of Canada, which means that companies can bring in and test their products and obtain a HACCP (Hazard Analysis Critical Control Points) certificate of analysis so that they can export that product overseas.

“Most companies don’t have labs, so we help them to set up HACCP systems and we also help them with the analysis,” Smith says.

Senior Microbiologist and Lab Manager, Ebo Budu-Amoako, oversees everything at Bio|Food|Tech related to food safety and food microbiology, as well as managing lab resources and consulting with the food industry.

“We work by forming partnerships to become an integral part of the client’s business and supply chain through analytical and quality assurance services,” he says. “We become like an extension of their quality control division. We work for them on a daily basis, we get samples here, and we provide results to them on a daily basis for them to be able to meet these objectives.”

Budu-Amoako’s main focus, and that of his team, is food pathogens like E. coli, Listeria, Salmonella and Vibrio. When there is an outbreak, such as the 2008 Listeria outbreak at a Maple Leaf Foods plant or the 2012 E. coli outbreak in Alberta, Bio|Food|Tech springs into action. It can conduct a needs assessment for a client, or a gap analysis as Budu-Amoako calls it, and work to fill that gap with the necessary food safety training and documentation.

“We assist food processing plants in instituting quality and food safety management systems, particularly based on the HACCP food safety system,” he says. “Sometimes the company would have persistent Listeria problems in its products and they would want to know the source of it. We would go to their plant and do an environmental survey, take samples from various areas of the plant, and then we analyze these samples to see where the problems are coming from.” Once the problem area has been identified, the client would revise their cleaning procedures or even change the type of cleaners used. Then they would retest until they achieved three or five subsequent negatives.

In 2015, when a Vibrio problem developed in the British Columbia oyster industry, Bio|Food|Tech was able to put together a risk assessment workshop and present it to industry stakeholders in the Atlantic provinces and B.C.

Bio|Food|Tech is also often called in to support the work of Canadian Food Inspection Agency (CFIA), Environment Canada or the Department of Health on PEI by analyzing samples for food-borne illnesses, Budu-Amoako says. For instance, Environment Canada tests the water quality in areas where shellfish are grown and brings the samples to Bio|Food|Tech to be analyzed for the presence of harmful microorganisms.

“This information is used to do classification of the growing or harvesting areas,” Budu-Amoako says. “It could result in approving the harvesting area, conditionally approving, restricting, conditionally restricting or prohibiting taking samples from those areas.”

Bio|Food|Tech also works with the beef industry on PEI to provide fast microbial testing results for the production of ground meat.

“They are required to test for E. coli on every batch of meat product that they are going to grind into ground beef, so they have to have their results before they do the grinding,” Budu-Amoako says. “What we do is we provide them with a thermos, they bring their sample today and the next morning, six o’clock in the morning, they have their results.”

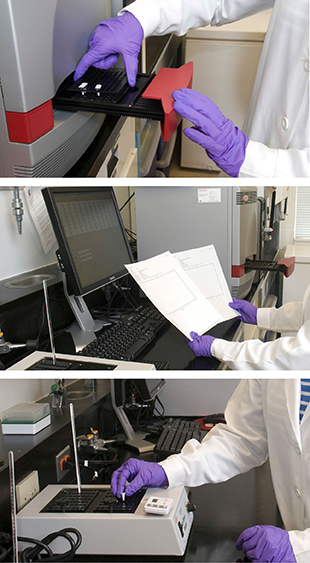

The BAX System is Bio|Food|Tech’s secret weapon. The PCR-based analytical system has the ability to do rapid analysis of food samples so clients can get results quickly and be back in business the next day.

“Analysis of pathogens like Salmonella, that might have taken four days with the traditional method, we will use the BAX System to get the results in about 24 hours,” Budu-Amoako says.

Along with the BAX System and other PCR machines that do molecular determination work, Bio|Food|Tech also makes use of various sensors in its shelf life and thermal processing work. To test whether the thermal processing of canned goods meets CFIA standards, for example, they insert sensors into a can before placing it into a machine like a huge pressure cooker, Smith says. Tests are done to determine whether the thermal processing is properly calibrated to kill certain bacteria on the food.

“We can put the bacteria on the food and then subject it to [various] time-temperatures to see what time-temperature would result in completely destroying the bacteria,” Budu-Amoako says. “Those would become the process parameters.”

But technology is not everything, he says. “All the employees working in the lab are highly skilled and highly trained. We have some elite scientists and technicians here that make all the difference in the world,” Budu-Amoako says. “It really does come down to people sometimes. You need the right equipment, but you really need the people who know how to use that equipment.”

There are two teams at Bio|Food|Tech that are integral to its operations: the food science group, which runs the pilot plants, and the microbiology group, which Budu-Amoako describes as “the technical services group” who also support the work the pilot plant does.

“Everything that has to go out from here or everything that we do in the pilot plant we would want to make sure that it’s of good quality and safe,” he says. “My lab also provides that support for internal product development.”

Bio|Food|Tech is part of the National Research Council (NRC) IRAP Contribution Agreement program, which allows it to work with small and medium-size Canadian companies on starter projects.

“It enables us [to work with a company] without any red tape, so there’s no form-filling, no money from the company,” Smith says. “All they have to do is call us up and ask us for help with a project.”

Most small and medium companies are so busy fighting fires it’s hard for them to be innovative, he says. “If they work with us we can provide them with the technical wherewithal to get a product into market.”

One company that has benefitted from Bio|Food|Tech’s expertise is Honibe. It approached the lab to see whether it was possible to make solid honey. The Bio|Food|Tech team started working on development and eventually began manufacturing the Honibe product for commercial sales. “They did that for two years before they moved into their own facility and they now have 50 people,” Smith says proudly. “And this is because of the support they could get from Bio|Food|Tech, both in the lab and in our pilot plants.”

Honibe is now an internationally renowned, award-winning company with products that are sold in more than 25 countries. Smith has several stories that are similar: like the orchard owner who needed a use for windfall apples and ended up developing apple brandy in Bio|Food|Tech’s fermentation and distillation workshop. Or the client that brought water from Cavendish Beach, PEI, looking for support to extract sea salt from it. “It’s kind of unexpected but it works,” Smith says.

From food safety to food product development, Bio|Food|Tech takes on every challenge the food industry throws its way. “Every day we get people coming to us and asking us to help them with something different,” Smith says. “The challenging thing is actually to get people to work with us in the first place. Once clients come and work with us, they’ll come back.”

BioLab Business Magazine Together, we reach farther into the Canadian Science community

BioLab Business Magazine Together, we reach farther into the Canadian Science community